HF300 Fluororubber Mold Release Agent

3. Good demoulding performance, production efficiency increased by 50%

4. Environmentally friendly, the defective ratio is reduced by 30%.

<b><div>Short Description</div></b> The introduction of fluorine atoms gives rubber excellent heat resistance, oxidation resistance, oil resistance, corrosion resistance and atmospheric aging resistance.</br> 1. Anti-oil, anti-fouling, protect the mold, prevent mold oxidation and rust..</br> 2.Dry film protection, low transfer, lasting effect up to 24 hours.<br> 3. Good demoulding performance, production efficiency increased by 50% <br> 4. Environmentally friendly, the defective ratio is reduced by 30%.<br>

3. Good demoulding performance, production efficiency increased by 50%

4. Environmentally friendly, the defective ratio is reduced by 30%.

所属分类:

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

- PRODUCT DETAIL

- APPLICATIONS SCOPE

- PRODUCT TAGS

-

- Commodity name: HF300 Fluororubber Mold Release Agent

<b><div>Short Description</div></b> The introduction of fluorine atoms gives rubber excellent heat resistance, oxidation resistance, oil resistance, corrosion resistance and atmospheric aging resistance.</br> 1. Anti-oil, anti-fouling, protect the mold, prevent mold oxidation and rust..</br> 2.Dry film protection, low transfer, lasting effect up to 24 hours.<br> 3. Good demoulding performance, production efficiency increased by 50% <br> 4. Environmentally friendly, the defective ratio is reduced by 30%.<br>

Product Paramenters

Product Model HF300 Specification 1KG/bottle, 5KG/bottle, two-component paint Features Suitable for demoulding silicone rubber with better effect Application Silicone mold release Function Oil resistant, stain resistant, Lasts 24 hours, environmental Release Principe Surface detachment Film Thickness Nanoscale Storage Life 1 year (from the date of production) Application:

The introduction of silicone atoms gives rubber excellent heat resistance, oxidation resistance, oil resistance, corrosion resistance and atmospheric aging resistance.

Performance advantages:

Anti-oil, anti-fouling, protect the mold, prevent mold oxidation and rust. Dry film protection, low transfer, lasts up to 24 hours. It has good demoulding performance, increases production efficiency by 50%, is environmentally friendly, and reduces the proportion of defects by 30%.

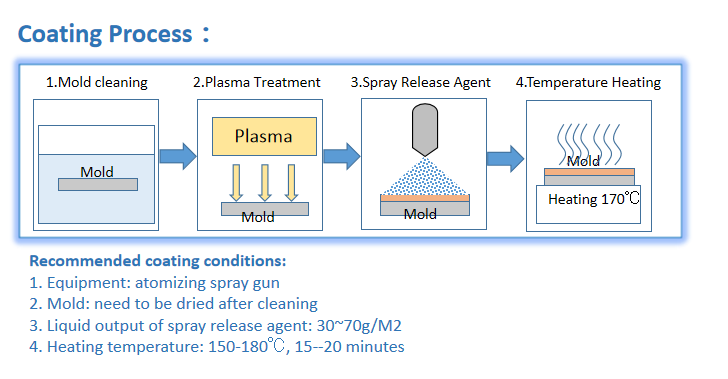

Processing method:

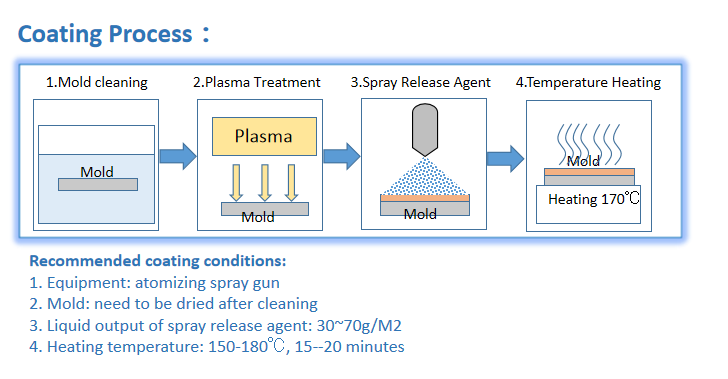

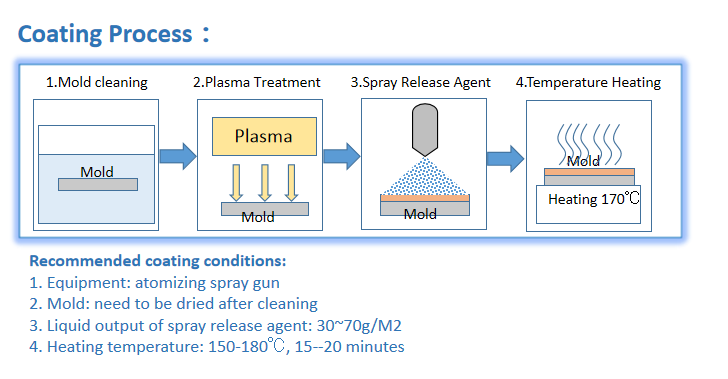

Mold cleaning ===》Plasma treatment ===》Spray release agent ===》Heating and heating

Release principle:

-

Scope of Application

HF300 Silicone Rubber Release Agent is suitable for food packaging, medical equipment, electronic products, cosmetics, automobile industry.

-

Release Agent

Mold Release

Releasing AgentMold Lubricant

Parting Agent

silicone Release Agent

PRODUCT DETAIL

Product Paramenters

| Product Model | HF300 |

| Specification | 1KG/bottle, 5KG/bottle, two-component paint |

| Features | Suitable for demoulding silicone rubber with better effect |

| Application | Silicone mold release |

| Function | Oil resistant, stain resistant, Lasts 24 hours, environmental |

| Release Principe | Surface detachment |

| Film Thickness | Nanoscale |

| Storage Life | 1 year (from the date of production) |

Application:

The introduction of silicone atoms gives rubber excellent heat resistance, oxidation resistance, oil resistance, corrosion resistance and atmospheric aging resistance.

Performance advantages:

Anti-oil, anti-fouling, protect the mold, prevent mold oxidation and rust. Dry film protection, low transfer, lasts up to 24 hours. It has good demoulding performance, increases production efficiency by 50%, is environmentally friendly, and reduces the proportion of defects by 30%.

Processing method:

Mold cleaning ===》Plasma treatment ===》Spray release agent ===》Heating and heating

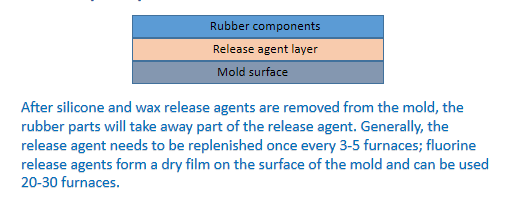

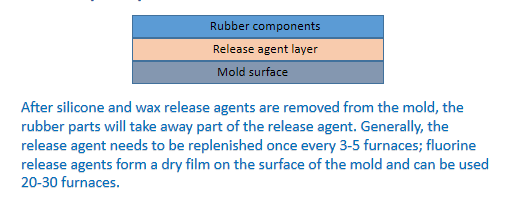

Release principle:

Related Products