HF8620 Fluorine-free C0 Water Repellent agent for 5 washing and dry at room tempreture

3. Great water repellency.

4. Meeting the requirements of ZDHC for zero emission of hazardous substances.

5. Processing will not affect the breathability of the fabric.

<b><div>Short Description</div></b> Non-Fluorinated C0 water repellent doesn't contain fluorine-based compounds. Compared with fluorine-based water repellent, it is not easy to deposit in organisms, easy to degrade, and harmless to the human body.</br> 1. Excluding APEO, PFOA, and PFOS.</br> 2. Meeting various of world environmental protection requirements.<br> 3. Great water repellency.<br> 4. Meeting the requirements of ZDHC for zero emission of hazardous substances.<br> 5. Processing will not affect the breathability of the fabric.<br>

3. Great water repellency.

4. Meeting the requirements of ZDHC for zero emission of hazardous substances.

5. Processing will not affect the breathability of the fabric.

所属分类:

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

- PRODUCT DETAIL

- APPLICATIONS SCOPE

- PRODUCT TAGS

-

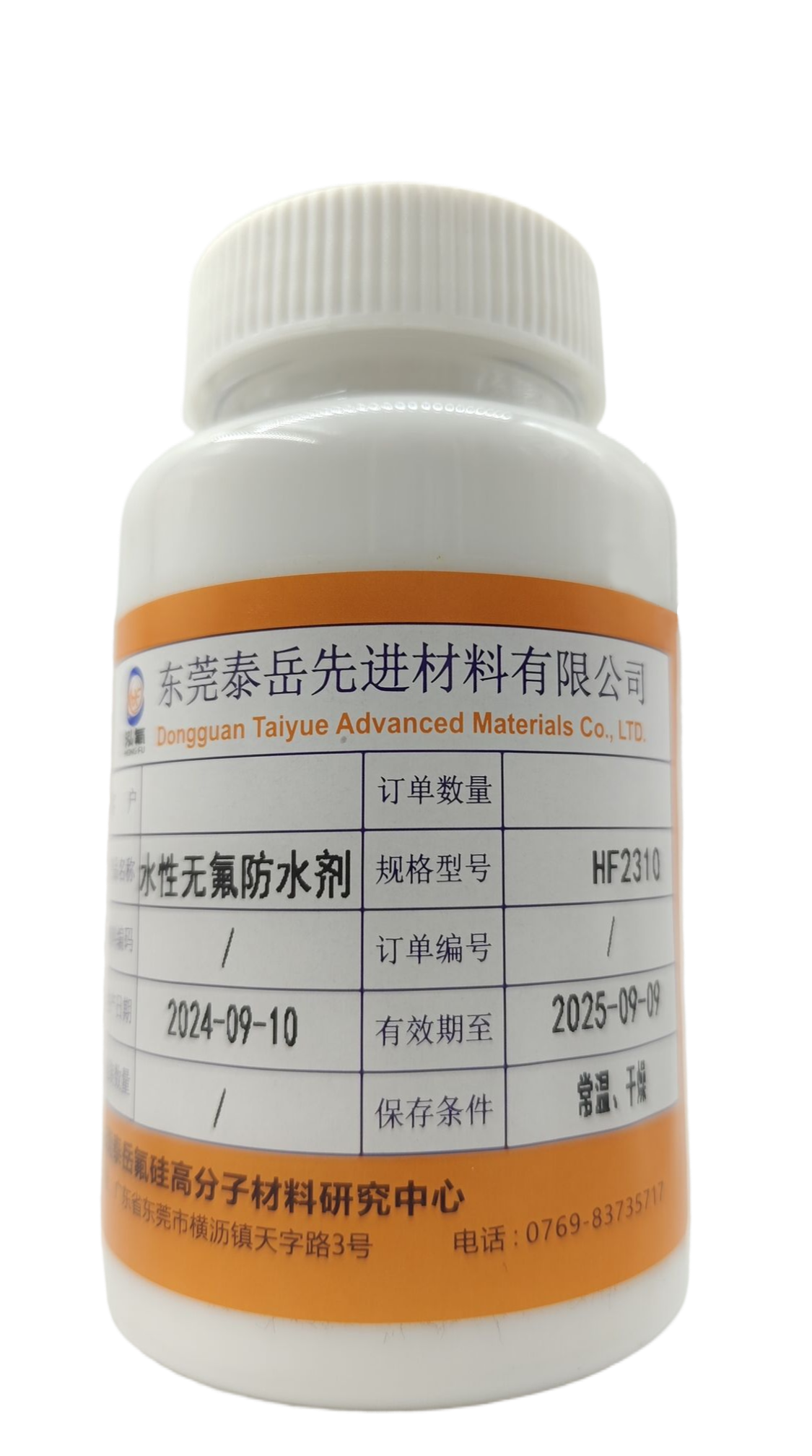

- Commodity name: HF8620 Fluorine-free C0 Water Repellent agent for 5 washing and dry at room tempreture

<b><div>Short Description</div></b> Non-Fluorinated C0 water repellent doesn't contain fluorine-based compounds. Compared with fluorine-based water repellent, it is not easy to deposit in organisms, easy to degrade, and harmless to the human body.</br> 1. Excluding APEO, PFOA, and PFOS.</br> 2. Meeting various of world environmental protection requirements.<br> 3. Great water repellency.<br> 4. Meeting the requirements of ZDHC for zero emission of hazardous substances.<br> 5. Processing will not affect the breathability of the fabric.<br>

Product Paramenters

Product Model HF8620 Fluorine-free C0 Water Repellent agent for 5 washing and dry at room tempreture Appearance white disersion Active Ingredient Modified Organosilicon Solid Content 26±1 Ionicity weak cation Storage Not higher than 30℃(86℉) and Not lower than 5℃(41℉) PH Value 5.5-6.0 Solubility easily solube in water Storage Life 1 year (from the date of production) Product Application

Fabric

Picking-up

Ratio%

Model

Dosage (g/L)

Drying/curing Conditions

Polyester Nylon

40-80

HF 8620

30-60g/L

Drying Temperature: 170°C -120S

Notice:

1. When using the auxiliary agent, HF 8620 must be completely dissolved and diluted before adding it.

2. To achieve maximum hydrophobicity, maintain the pH value of the bath at 4.0-5.5 .

Application examples

Spray test

Washable frequency and waterproofing grade

Fabric

Initial

Washable up to 5 times

Taslon

5

5

Dietrich

5

5

Spring Yafang

5

5

Nylon

5

5

HF 8620 Performance test results

Note: Fabric structure, fiber content, chemical additives, and processing conditions can affect performance. Please confirm with the laboratory before production operation.

Formula :

50g/L

Processing Conditions:

The bath solution has a pH of 5.5 and a cycle of 1 immersion and 1 pressurization.

Picking-up

Ratio% :

Polyester fiber 50%, Nylon 55%

Curing:

170 ℃ x 2 minutes

Washing Standards :

AATCC 124 ( 40 ℃ ), wash and air dry.

Waterproof Performance:

AATCC 22 Spray Test

Key words:- C0 Water Repellent

- 10 washing

-

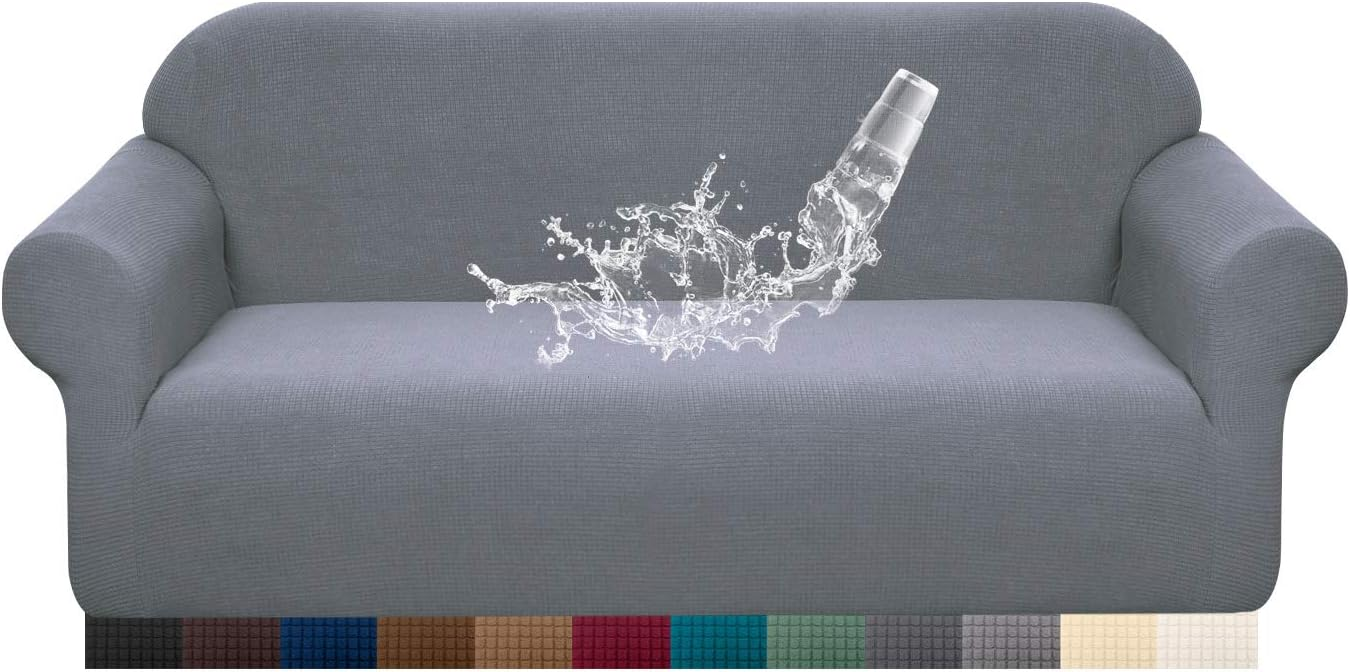

Scope of Application

Widely used in luggage cloth, tent cloth, shoe material fabric, outdoor clothing, tooling fabrics, industrial fabrics, pure cotton fabrics, clothing fabric, casual wear, umbrella cloth, etc.

-

Non-Fluorinated water repellent

C0 Water Repellent

Waterproofing Agent

Water Repellent Chemical

Hydrophobic Agent for Fabric

Fabrics Waterproof Chemicals

Textile Finished Treatment Agent

Fabric After Treatment Chemicals

Environmentally friendly

Hydrophobic spray for fabric

Hydrophobic agent

PRODUCT DETAIL

Product Paramenters

| Product Model | HF8620 Fluorine-free C0 Water Repellent agent for 5 washing and dry at room tempreture |

| Appearance | white disersion |

| Active Ingredient | Modified Organosilicon |

| Solid Content | 26±1 |

| Ionicity | weak cation |

| Storage | Not higher than 30℃(86℉) and Not lower than 5℃(41℉) |

| PH Value | 5.5-6.0 |

| Solubility | easily solube in water |

| Storage Life | 1 year (from the date of production) |

Product Application

|

Fabric |

Picking-up Ratio% |

Model |

Dosage (g/L) |

Drying/curing Conditions |

|

Polyester Nylon |

40-80 |

HF 8620 |

30-60g/L |

Drying Temperature: 170°C -120S |

Notice:

1. When using the auxiliary agent, HF 8620 must be completely dissolved and diluted before adding it.

2. To achieve maximum hydrophobicity, maintain the pH value of the bath at 4.0-5.5 .

Application examples

|

Spray test |

Washable frequency and waterproofing grade |

|

|

Fabric |

Initial |

Washable up to 5 times |

|

Taslon |

5 |

5 |

|

Dietrich |

5 |

5 |

|

Spring Yafang |

5 |

5 |

|

Nylon |

5 |

5 |

HF 8620 Performance test results

Note: Fabric structure, fiber content, chemical additives, and processing conditions can affect performance. Please confirm with the laboratory before production operation.

|

Formula : |

50g/L |

|

Processing Conditions: |

The bath solution has a pH of 5.5 and a cycle of 1 immersion and 1 pressurization. |

|

Picking-up Ratio% : |

Polyester fiber 50%, Nylon 55% |

|

Curing: |

170 ℃ x 2 minutes |

|

Washing Standards : |

AATCC 124 ( 40 ℃ ), wash and air dry. |

|

Waterproof Performance: |

AATCC 22 Spray Test |

Related Products