TY2308 PUR Reactive Heat-melting Adhesive

3. Easy to attach to various substrates.

4. Excellent chemical resistance, acid and alkali resistance and organic solvents.

5.Low moisture permeability (excellent moisture resistance).

6.After fixed line, elastic and ductile polymers can be formed, but they also have excellent flexibility.

7.Fast landline.

<b><div>Short Description</div></b> Polyurethane reactive (PUR) hot melt adhesive is the reaction product of a polyol mixture and a peroxydiisocyanate (such as MDI) and is solid at room temperature.</br> 1. Strong and durable, single component structure.</br> 2.Excellent strength for almost instant bonding.<br> 3. Easy to attach to various substrates. <br> 4. Excellent chemical resistance, acid and alkali resistance and organic solvents.<br> 5.Low moisture permeability (excellent moisture resistance).<br> 6.After fixed line, elastic and ductile polymers can be formed, but they also have excellent flexibility.<br> 7.Fast landline.<br>

3. Easy to attach to various substrates.

4. Excellent chemical resistance, acid and alkali resistance and organic solvents.

5.Low moisture permeability (excellent moisture resistance).

6.After fixed line, elastic and ductile polymers can be formed, but they also have excellent flexibility.

7.Fast landline.

所属分类:

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

- PRODUCT DETAIL

- APPLICATIONS SCOPE

- PRODUCT TAGS

-

- Commodity name: TY2308 PUR Reactive Heat-melting Adhesive

<b><div>Short Description</div></b> Polyurethane reactive (PUR) hot melt adhesive is the reaction product of a polyol mixture and a peroxydiisocyanate (such as MDI) and is solid at room temperature.</br> 1. Strong and durable, single component structure.</br> 2.Excellent strength for almost instant bonding.<br> 3. Easy to attach to various substrates. <br> 4. Excellent chemical resistance, acid and alkali resistance and organic solvents.<br> 5.Low moisture permeability (excellent moisture resistance).<br> 6.After fixed line, elastic and ductile polymers can be formed, but they also have excellent flexibility.<br> 7.Fast landline.<br>

Product Paramenters

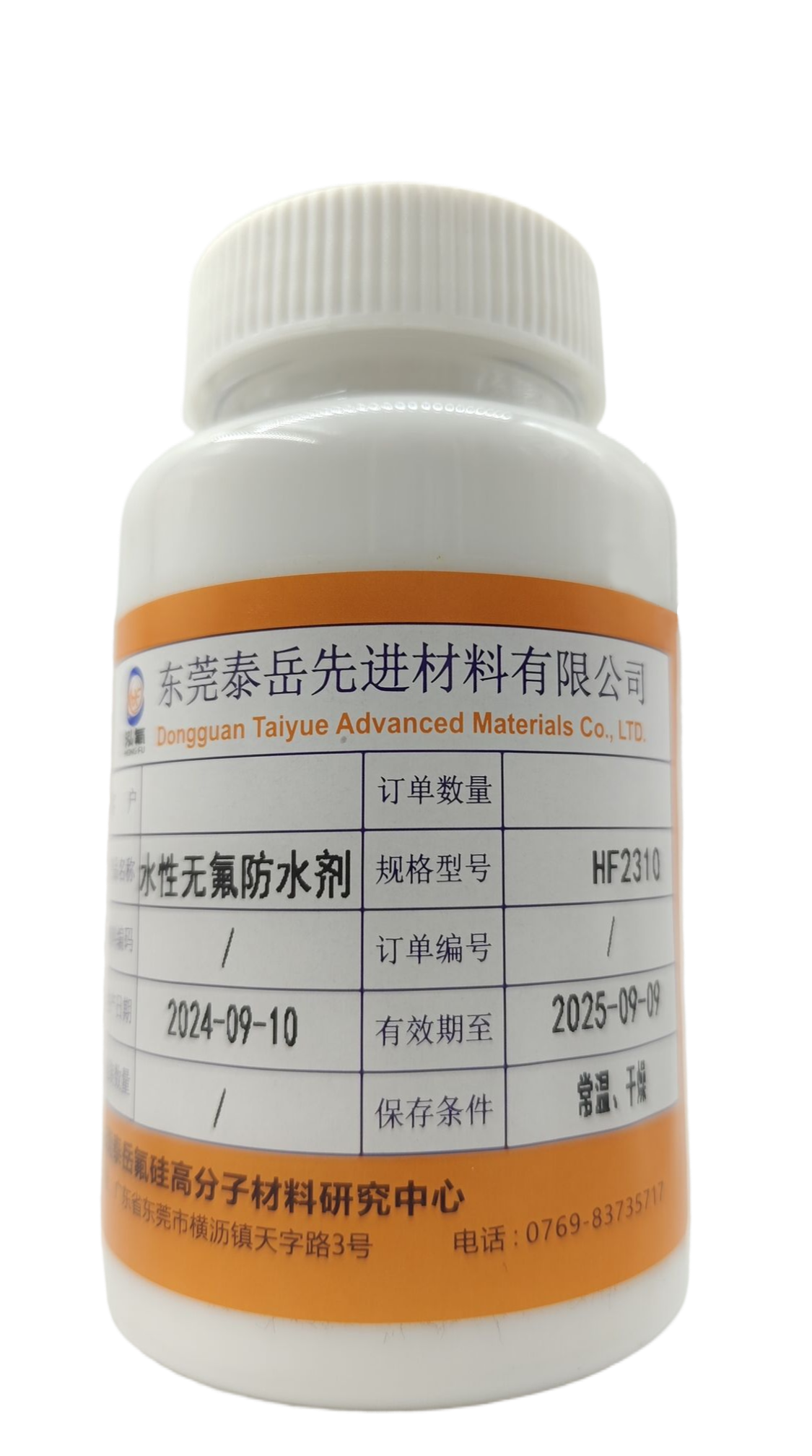

Product Model TY2308 Technology Heating -Dissolution Appearance Light Yellow Application Packaging, auto parts, building materials, electronic equipment, such as book binding, lamp bonding, sheet edge sealing Function Easy sizing, fast fixed-line, high initial viscosity, good heat resistance, moisture, chemical resistance, giving the substrate excellent sealing, environmental Storage Air Drying Storage Life 1 year (from the date of production) Application:

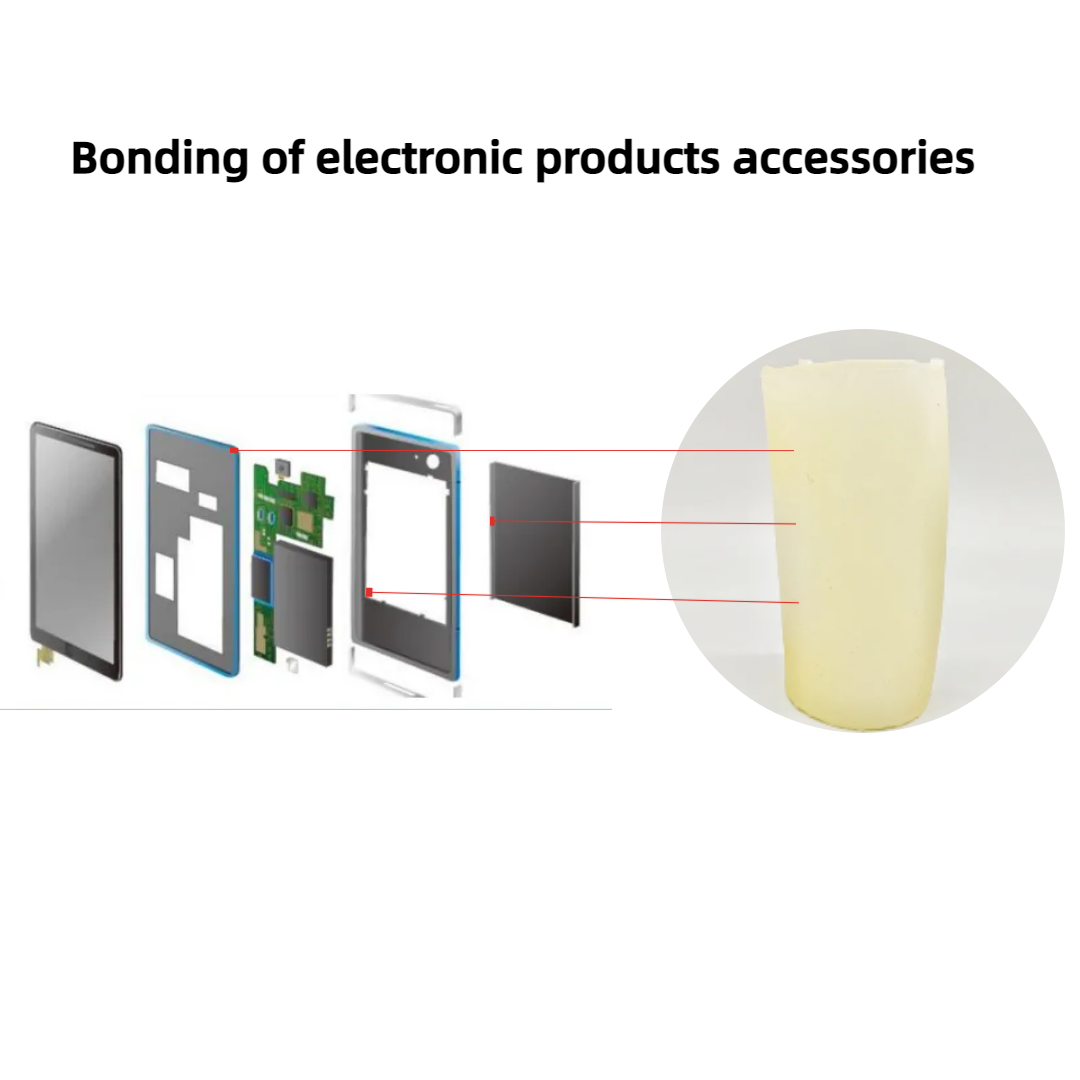

PUR reactive hot melt adhesive family includes products specifically designed for mobile device assembly, with a range of performance properties including impact, chemical, moisture and temperature resistance, making them suitable for a wide range of applications from touch panel assembly to mobile phone component bonding. Different applications in the field.

Market and Application:

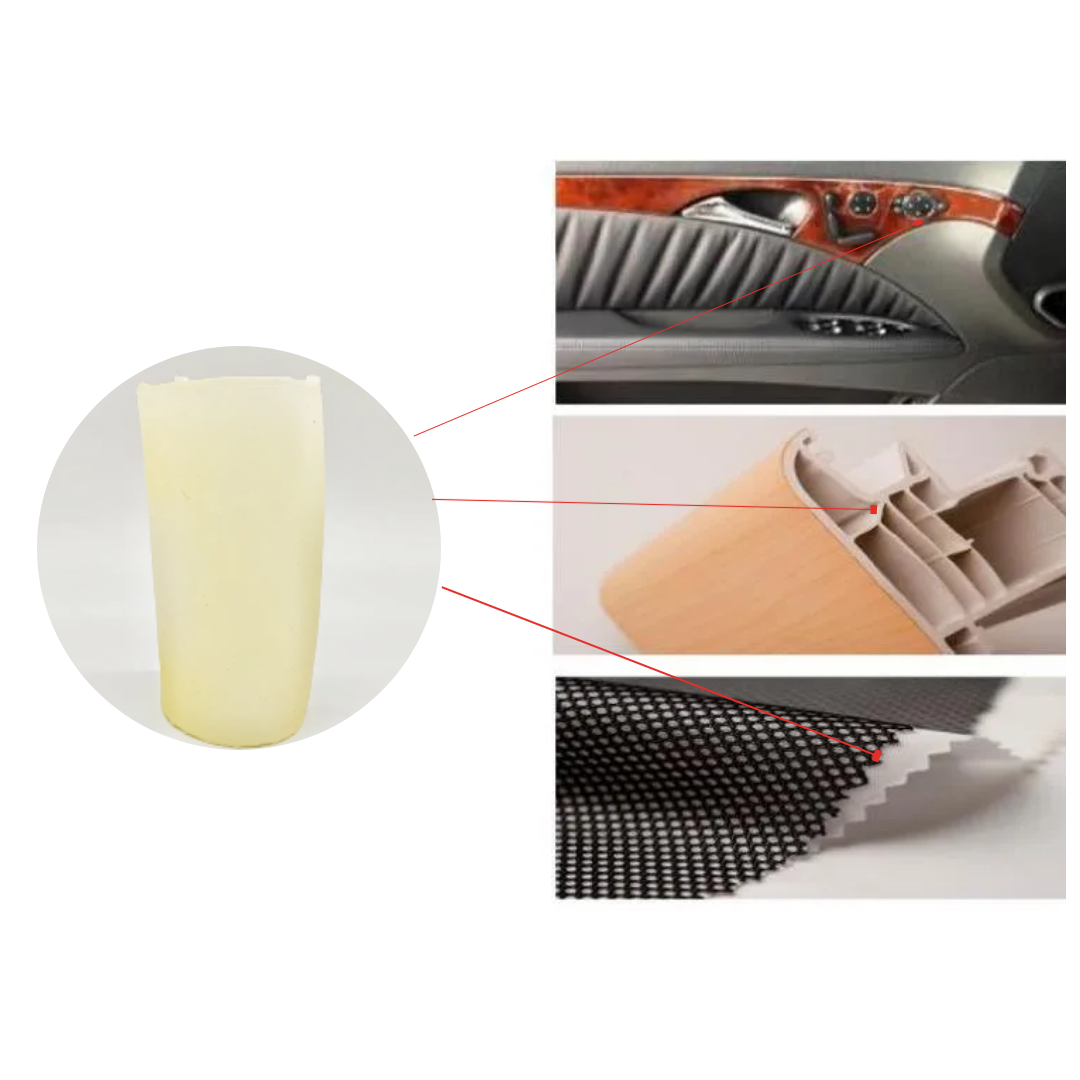

Auto Industry

(e.g. automotive interior parts, door panels, windshield bonding)

Wood Products Industry

(e.g. edge trim, profile wrapping, flat laminate, parquet flooring)

Packaging Industry/Graphic Arts

(e.g. folding boxes, binding)

Achitechive

(e.g. flat lamination, sandwich construction)

Textile Industry

(e.g. protective clothing, sportswear, medical applications, healthcare)Processing:

MDI (solid) ===》Filler + calcium carbonate ===》Dehydration completed ===》Polyol mixture ===》Sealed packaging (solid rubber)

Features:

It is easy to apply glue, fast to fix, has high initial viscosity, good heat resistance, moisture-proof, chemical resistance, environmental protection, gives the base material excellent sealing properties, and has a wide range of applications.

Apply material:

Metal, wood, glass, leather, plastic.

Application scope:

Packaging, auto parts, building materials, electronic equipment, such as book binding, car light bonding, sheet patch edge sealing, especially narrowing and thinning of screen borders for electronic equipment, electromechanical, and aerospace -

Scope of Application

PUR Reactive Heat-melting Adhesive can be used at packaging, auto parts, building materials, electronic equipment, such as book binding, car light bonding, sheet patch edge sealing, especially narrowing and thinning of screen borders for electronic equipment, electromechanical, and aerospace

-

Hot melt adhesive for bonding fabric

Hot cementHot melt adhesive glue

Hot melt adhesive stick

Reactive heat-melting adhesive

PRODUCT DETAIL

Product Paramenters

| Product Model | TY2308 |

| Technology | Heating -Dissolution |

| Appearance | Light Yellow |

| Application | Packaging, auto parts, building materials, electronic equipment, such as book binding, lamp bonding, sheet edge sealing |

| Function | Easy sizing, fast fixed-line, high initial viscosity, good heat resistance, moisture, chemical resistance, giving the substrate excellent sealing, environmental |

| Storage | Air Drying |

| Storage Life | 1 year (from the date of production) |

Application:

PUR reactive hot melt adhesive family includes products specifically designed for mobile device assembly, with a range of performance properties including impact, chemical, moisture and temperature resistance, making them suitable for a wide range of applications from touch panel assembly to mobile phone component bonding. Different applications in the field.

Market and Application:

Auto Industry

(e.g. automotive interior parts, door panels, windshield bonding)

Wood Products Industry

(e.g. edge trim, profile wrapping, flat laminate, parquet flooring)

Packaging Industry/Graphic Arts

(e.g. folding boxes, binding)

Achitechive

(e.g. flat lamination, sandwich construction)

Textile Industry

(e.g. protective clothing, sportswear, medical applications, healthcare)

Processing:

MDI (solid) ===》Filler + calcium carbonate ===》Dehydration completed ===》Polyol mixture ===》Sealed packaging (solid rubber)

Features:

It is easy to apply glue, fast to fix, has high initial viscosity, good heat resistance, moisture-proof, chemical resistance, environmental protection, gives the base material excellent sealing properties, and has a wide range of applications.

Apply material:

Metal, wood, glass, leather, plastic.

Application scope:

Packaging, auto parts, building materials, electronic equipment, such as book binding, car light bonding, sheet patch edge sealing, especially narrowing and thinning of screen borders for electronic equipment, electromechanical, and aerospace

Related Products