HF1702 Conformal Coating

3. Oxidation resistance.

4. salt resistance.

5.Corrosion-resistant, nano ultra-thin, quick-drying.

<b><div>Short Description</div></b> Suitable for various intelligent electronic products, waterproof, moisture-proof, corrosion-resistant, nano ultra-thin, quick-drying.</br> 1. Excellent super waterproof.</br> 2. Moisture-proof, insulation.<br> 3. Oxidation resistance.<br> 4. salt resistance.<br> 5.Corrosion-resistant, nano ultra-thin, quick-drying.<br>

3. Oxidation resistance.

4. salt resistance.

5.Corrosion-resistant, nano ultra-thin, quick-drying.

所属分类:

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

- PRODUCT DETAIL

- APPLICATIONS SCOPE

- PRODUCT TAGS

-

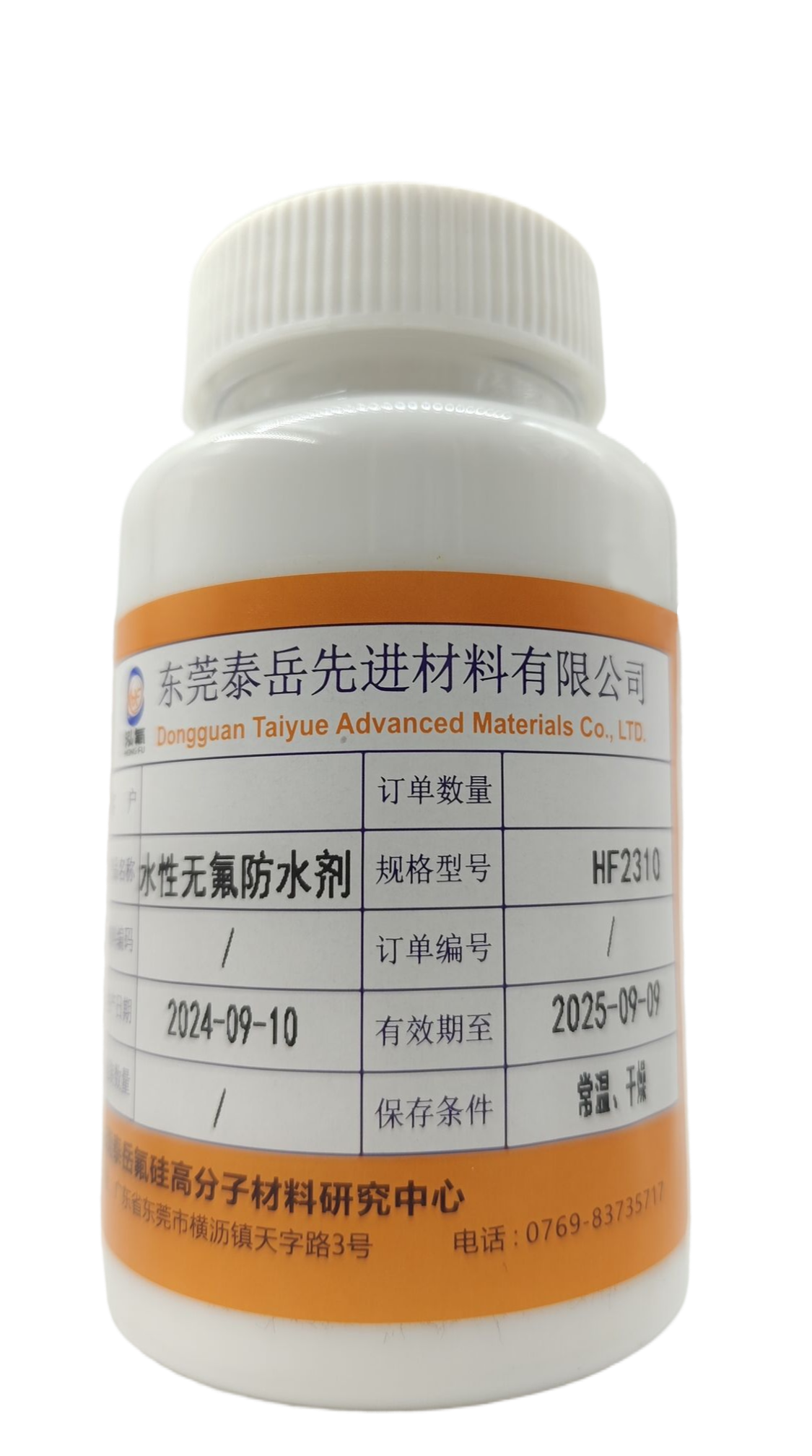

- Commodity name: HF1702 Conformal Coating

<b><div>Short Description</div></b> Suitable for various intelligent electronic products, waterproof, moisture-proof, corrosion-resistant, nano ultra-thin, quick-drying.</br> 1. Excellent super waterproof.</br> 2. Moisture-proof, insulation.<br> 3. Oxidation resistance.<br> 4. salt resistance.<br> 5.Corrosion-resistant, nano ultra-thin, quick-drying.<br>

Product Paramenters

Product Model HF1702 Appearance Light yellow Classification Chemical Auxiliary Agent Solid Content 2% Application Using on the surface of circuit board Function Hydrophobic, Moisture-proof, Oxidation resistant, Salt resistant Salt Spray Test ≥48 hours Specific Gravity 0.85 Storage Life 1 year (from the date of production) Application:

Water and oil repellent is generally used in the final process, ribbon, thread must be cleaned as far as possible after dyeing, do not contain any acid, alkali, salt or surfactant, so as to ensure uniform water and oil repellent finishing effect.

Product Description:

HF-1700 series electronic protective agent is a colorless and transparent liquid, non-toxic and environmentally friendly, and has no obvious odor. The product uses fluorine-containing solvent as the medium, and can quickly form a thin, transparent, and almost invisible protective film (2~5μm) on the surface of the workpiece when used. It has excellent super waterproof, moisture-proof, insulation, oxidation resistance, and salt resistance. Fog and other functions can effectively solve the phenomenon of PCB short circuit and even burnout caused by accidental falling into the water, sweating, and rain in daily life.

Processing method:

Smearing: It is recommended to use a row brush.

Spraying: It is recommended to use professional nano spraying equipment.

Soaking: Directly immerse the electronic components in the product for 10s, take it out, and let it dry naturally.

Transportation and storage:

1.Transport as non-dangerous goods, avoid heat, moisture or severe vibration during transportation;

2.It should be stored in a well-ventilated environment at 0-20℃, away from strong alkalis and heat sources.

Matters needing attention:

Make sure that the electronic product is clean before coating and use, and tighten the bottle cap in time if it is not used after the package is unpacked;

When using, make sure that the product is evenly coated on the electronic components and air-dried naturally at room temperature;

Considering that the coating is not scratch-resistant and has low adhesion, it can be scraped off with a soft plastic sheet (provided it does not damage the substrate), or the coating can be completely removed by ultrasonic soaking in a fluorinated liquid solvent.

-

Scope of Application

HF-1700 Series is suitable for various intelligent electronic products, waterproof, moisture-proof, corrosion-resistant, nano ultra-thin, quick-drying

-

Conformal Coating

Conformal Coating Agent

Waterproof Agent

Silicone Conformal Coating

Conformal Coating for Pcb

Moisture-proofing Fluid PCB

PRODUCT DETAIL

Product Paramenters

| Product Model | HF1702 |

| Appearance | Light yellow |

| Classification | Chemical Auxiliary Agent |

| Solid Content | 2% |

| Application | Using on the surface of circuit board |

| Function | Hydrophobic, Moisture-proof, Oxidation resistant, Salt resistant |

| Salt Spray Test | ≥48 hours |

| Specific Gravity | 0.85 |

| Storage Life | 1 year (from the date of production) |

Application:

Water and oil repellent is generally used in the final process, ribbon, thread must be cleaned as far as possible after dyeing, do not contain any acid, alkali, salt or surfactant, so as to ensure uniform water and oil repellent finishing effect.

Product Description:

HF-1700 series electronic protective agent is a colorless and transparent liquid, non-toxic and environmentally friendly, and has no obvious odor. The product uses fluorine-containing solvent as the medium, and can quickly form a thin, transparent, and almost invisible protective film (2~5μm) on the surface of the workpiece when used. It has excellent super waterproof, moisture-proof, insulation, oxidation resistance, and salt resistance. Fog and other functions can effectively solve the phenomenon of PCB short circuit and even burnout caused by accidental falling into the water, sweating, and rain in daily life.

Processing method:

Smearing: It is recommended to use a row brush.

Spraying: It is recommended to use professional nano spraying equipment.

Soaking: Directly immerse the electronic components in the product for 10s, take it out, and let it dry naturally.

Transportation and storage:

1.Transport as non-dangerous goods, avoid heat, moisture or severe vibration during transportation;

2.It should be stored in a well-ventilated environment at 0-20℃, away from strong alkalis and heat sources.

Matters needing attention:

Make sure that the electronic product is clean before coating and use, and tighten the bottle cap in time if it is not used after the package is unpacked;

When using, make sure that the product is evenly coated on the electronic components and air-dried naturally at room temperature;

Considering that the coating is not scratch-resistant and has low adhesion, it can be scraped off with a soft plastic sheet (provided it does not damage the substrate), or the coating can be completely removed by ultrasonic soaking in a fluorinated liquid solvent.

Related Products