Anti-UV Anti-fingerprint Agent

3. Reduce friction coefficient.

4. Easy to clean.

5. High wear resistance,Anti-UV.

6. Improve acid and alkali resistance.

<b><div>Short Description</div></b> Fluorosilicone Polymer Anti-fingerprint Agent for Anti-UV.</br> 1. Waterproof.</br> 2. Oil resistance,anti-fingerprint.<br> 3. Reduce friction coefficient.<br> 4. Easy to clean.<br> 5. High wear resistance,Anti-UV. <br> 6. Improve acid and alkali resistance. <br>

3. Reduce friction coefficient.

4. Easy to clean.

5. High wear resistance,Anti-UV.

6. Improve acid and alkali resistance.

所属分类:

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

- PRODUCT DETAIL

- APPLICATIONS SCOPE

- PRODUCT TAGS

-

- Commodity name: Anti-UV Anti-fingerprint Agent

<b><div>Short Description</div></b> Fluorosilicone Polymer Anti-fingerprint Agent for Anti-UV.</br> 1. Waterproof.</br> 2. Oil resistance,anti-fingerprint.<br> 3. Reduce friction coefficient.<br> 4. Easy to clean.<br> 5. High wear resistance,Anti-UV. <br> 6. Improve acid and alkali resistance. <br>

Product Paramenters

Product Model Anti-UV Anti-fingerprint Agent Appearance Transparent Solid Content 20% Application Anti-UV for glass materials field Function Anti-fingerprint, oil-resistant,abrasive resistant,Anti-UV Initial Water Contact Angle 110°-120° Storage In an airtight container (20°C). Storage Life 1 year (from the date of production) Introduction

Fluorine-containing polymer surface treatment agent, by forming a monomolecular film sequential thin film coating on the surface of glass, and it have a good adhesive resistance. it has excellent Anti-UV, waterproof, oil resistance, antifouling and lubricating properties without affecting the appearance of the product. It can be coated by spraying, dipping, vacuum plating, etc.

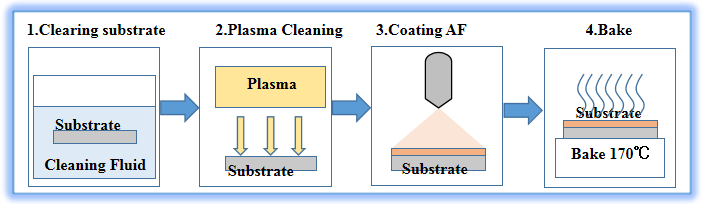

Application: Coating Technology

1.Evaporation

Suggested Coating Conditions:

1. Substrate: After cleaning, it needs to be dried before use

2. Equipment: vacuum coating machine

3. Vacuum degree: less than 7.0E-3 Pa

4. Film thickness of vacuum coating: SiO2, 8~10nm; AF, 10~17nm2.Spray Coating

Suggested coating conditions:

1. Equipment: spraying machine

2. The main agent is used after being diluted according to the performance requirements

3. Substrate: after cleaning, it needs to be dried before use

4. The water droplet angle of the substrate after plasma treatment is less than 40°

5. Liquid output: 30~70g/M2

6. Baking conditions: 150-170℃, baking for 30 minutes3.Soaking

Suggested coating conditions:

1. Equipment: Container

2. The main agent is used after being diluted according to the performance requirements

3. Substrate: after cleaning, it needs to be dried before use

4. The water droplet angle of the substrate after plasma treatment is less than 40°

5. Soaking time: more than 1 minute

6. Take-out speed: 5~15mm/sec

6. Baking conditions: 150-170℃, baking for 30 minutes -

Scope of Application

Anti-UV Anti-fingerprint Agent can be used at glass materials, like phone cover lens, back cover, phones display, glasses, camera lens, car touching panel, etc.

-

Anti-UV agent

AF agent

hydrophobic agent

nano coating hydrophobic

glass water repellent for anti-UV

PRODUCT DETAIL

Product Paramenters

| Product Model | Anti-UV Anti-fingerprint Agent |

| Appearance | Transparent |

| Solid Content | 20% |

| Application | Anti-UV for glass materials field |

| Function | Anti-fingerprint, oil-resistant,abrasive resistant,Anti-UV |

| Initial Water Contact Angle | 110°-120° |

| Storage | In an airtight container (20°C). |

| Storage Life | 1 year (from the date of production) |

Introduction

Fluorine-containing polymer surface treatment agent, by forming a monomolecular film sequential thin film coating on the surface of glass, and it have a good adhesive resistance. it has excellent Anti-UV, waterproof, oil resistance, antifouling and lubricating properties without affecting the appearance of the product. It can be coated by spraying, dipping, vacuum plating, etc.

Application: Coating Technology

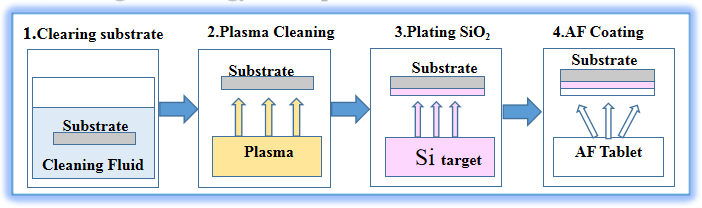

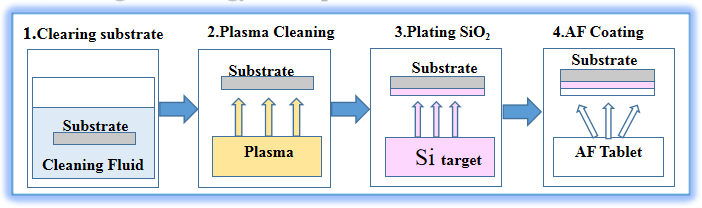

1.Evaporation

Suggested Coating Conditions:

1. Substrate: After cleaning, it needs to be dried before use

2. Equipment: vacuum coating machine

3. Vacuum degree: less than 7.0E-3 Pa

4. Film thickness of vacuum coating: SiO2, 8~10nm; AF, 10~17nm

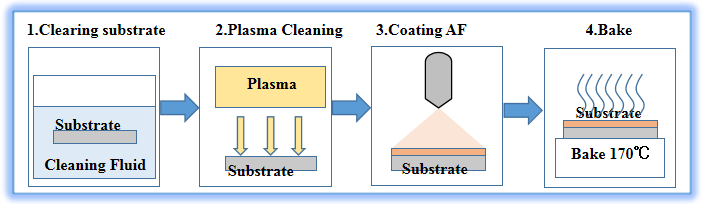

2.Spray Coating

Suggested coating conditions:

1. Equipment: spraying machine

2. The main agent is used after being diluted according to the performance requirements

3. Substrate: after cleaning, it needs to be dried before use

4. The water droplet angle of the substrate after plasma treatment is less than 40°

5. Liquid output: 30~70g/M2

6. Baking conditions: 150-170℃, baking for 30 minutes

3.Soaking

Suggested coating conditions:

1. Equipment: Container

2. The main agent is used after being diluted according to the performance requirements

3. Substrate: after cleaning, it needs to be dried before use

4. The water droplet angle of the substrate after plasma treatment is less than 40°

5. Soaking time: more than 1 minute

6. Take-out speed: 5~15mm/sec

6. Baking conditions: 150-170℃, baking for 30 minutes

Related Products