Antibacterial Anti-fingerprint Agent

3. Reduce friction coefficient.

4. Easy to clean.

5. High wear resistance.

<b><div>Short Description</div></b> Fluorosilicone Polymer Antibacterial agent.</br> 1. Waterproof.</br> 2. Oil resistance, anti-fingerprint. Stain Resistance.<br> 3. Reduce friction coefficient.<br> 4. Easy to clean.<br> 5. High wear resistance. <br>

3. Reduce friction coefficient.

4. Easy to clean.

5. High wear resistance.

所属分类:

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

这里是占位文字

- PRODUCT DETAIL

- APPLICATIONS SCOPE

- PRODUCT TAGS

-

- Commodity name: Antibacterial Anti-fingerprint Agent

<b><div>Short Description</div></b> Fluorosilicone Polymer Antibacterial agent.</br> 1. Waterproof.</br> 2. Oil resistance, anti-fingerprint. Stain Resistance.<br> 3. Reduce friction coefficient.<br> 4. Easy to clean.<br> 5. High wear resistance. <br>

Product Paramenters

Product Model Antibacterial Anti-fingerprint Agent Appearance Transparent Solid Content 20% Application Glass materials field Function Anti-fingerprint, Oil resistance,Antibacterial Resistance Initial Water Contact Angle 110°-120° Storage In an airtight container (20°C). Storage Life 1 year (from the date of production) Introduction

Fluorine-containing polymer surface treatment agent, by forming a monomolecular film sequential thin film coating on the surface of glass materials, it has excellent Antibacterial waterproof, oil resistance, antifouling and lubricating properties without affecting the appearance of the product. It can be coated by spraying, dipping, vacuum plating, etc.

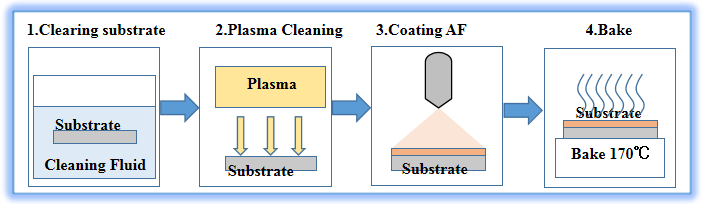

Application: Coating Technology

1.Evaporation

Suggested Coating Conditions:

1. Substrate: After cleaning, it needs to be dried before use

2. Equipment: vacuum coating machine

3. Vacuum degree: less than 7.0E-3 Pa

4. Film thickness of vacuum coating: SiO2, 8~10nm; AF, 10~17nm2.Spray Coating

Suggested coating conditions:

1. Equipment: spraying machine

2. The main agent is used after being diluted according to the performance requirements

3. Substrate: after cleaning, it needs to be dried before use

4. The water droplet angle of the substrate after plasma treatment is less than 40°

5. Liquid output: 30~70g/M2

6. Baking conditions: 150-170℃, baking for 30 minutes3.Soaking

Suggested coating conditions:

1. Equipment: Container

2. The main agent is used after being diluted according to the performance requirements

3. Substrate: after cleaning, it needs to be dried before use

4. The water droplet angle of the substrate after plasma treatment is less than 40°

5. Soaking time: more than 1 minute

6. Take-out speed: 5~15mm/sec

6. Baking conditions: 150-170℃, baking for 30 minutes -

Scope of Application

Anti-fingerprint Agent for Antibacterial Resistance can be used at glass materials, like phone cover lens, back cover, phones display, glasses, camera lens, car touching panel, etc.

-

Antibacterial agent

AF agent

hydrophobic agent

nano coating hydrophobic

Hydrophobic antibacterial coating liquid

PRODUCT DETAIL

Product Paramenters

| Product Model | Antibacterial Anti-fingerprint Agent |

| Appearance | Transparent |

| Solid Content | 20% |

| Application | Glass materials field |

| Function | Anti-fingerprint, Oil resistance,Antibacterial Resistance |

| Initial Water Contact Angle | 110°-120° |

| Storage | In an airtight container (20°C). |

| Storage Life | 1 year (from the date of production) |

Introduction

Fluorine-containing polymer surface treatment agent, by forming a monomolecular film sequential thin film coating on the surface of glass materials, it has excellent Antibacterial waterproof, oil resistance, antifouling and lubricating properties without affecting the appearance of the product. It can be coated by spraying, dipping, vacuum plating, etc.

Application: Coating Technology

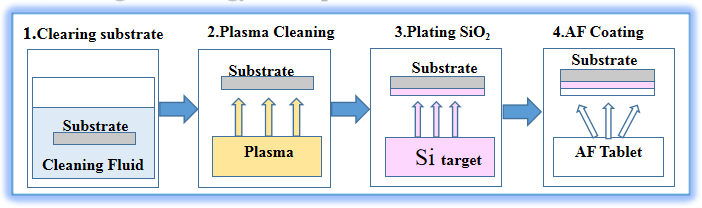

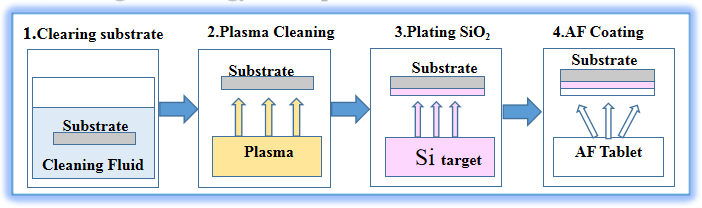

1.Evaporation

Suggested Coating Conditions:

1. Substrate: After cleaning, it needs to be dried before use

2. Equipment: vacuum coating machine

3. Vacuum degree: less than 7.0E-3 Pa

4. Film thickness of vacuum coating: SiO2, 8~10nm; AF, 10~17nm

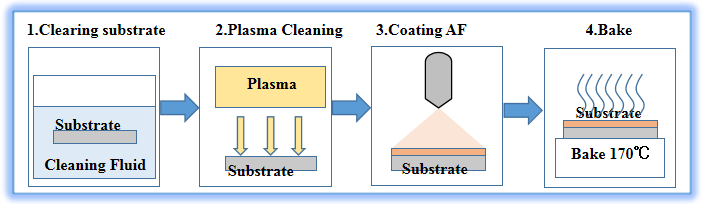

2.Spray Coating

Suggested coating conditions:

1. Equipment: spraying machine

2. The main agent is used after being diluted according to the performance requirements

3. Substrate: after cleaning, it needs to be dried before use

4. The water droplet angle of the substrate after plasma treatment is less than 40°

5. Liquid output: 30~70g/M2

6. Baking conditions: 150-170℃, baking for 30 minutes

3.Soaking

Suggested coating conditions:

1. Equipment: Container

2. The main agent is used after being diluted according to the performance requirements

3. Substrate: after cleaning, it needs to be dried before use

4. The water droplet angle of the substrate after plasma treatment is less than 40°

5. Soaking time: more than 1 minute

6. Take-out speed: 5~15mm/sec

6. Baking conditions: 150-170℃, baking for 30 minutes

Related Products